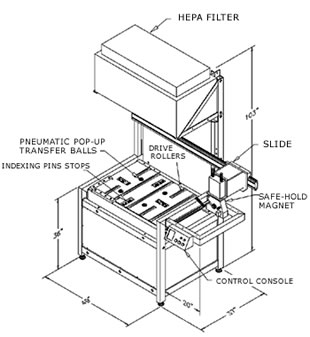

Advantages of the LS-350

The C.A.PICARD® modular lay-up station provides manufacturers the ability to greatly improve the productivity of their lamination process. The system is easily designed to match your operation. Through the thoughtful ergonomic design lay-up is greatly simplified. The result is increased operator productivity and reduction of handling damage and particulate contamination.

Specifications

- Mobile kit cart docks to lay-up station

- Three adjustable shelves

- Pull out lamination plate drawer interfaces with safe hold magnet

- Pull out separator / CAC drawer

- Semi-automatic lamination plate lifter with safe-hold magnet

- Automatic finished book out feed

- Adjustable pin stops

- Max. lamination plate 24" x 30" Min. 10" x 12"

Operation

- Work order kits are loaded on a mobile cart.

- Kitted pre-preg, inner-layers, lamination plates, separator plates, CAC, and load leveler all have an ergonomic storage location.

- Transport and dock the kit cart to the lay-up station.

- Pull out the lamination plate drawer.

- Utilize the safe hold magnet to lift and manipulate the lamination plates from the pull out drawer to the lay-up table.

- Actuate the pin stops.

- Build the work order by pulling product from the ergonomically placed shelves and drawers.

- Utilize the safe-hold magnet to lift and place the top lamination plate.

- Automatically send the finished book out to the press area.