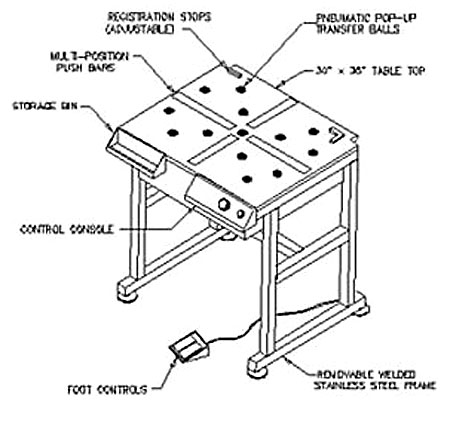

PinLam LS-150 basic lay-up station

The C.A.PICARD® basic lay-up station provides manufacturers improved lamination processes. The system is easily designed to match your operation. The lay-up station can be a standalone work station, or the support frame can be removed for placement in your existing production line. The result is increased operator productivity and reduction of handling damage and particulate contamination.

Specifications

- Pneumatic pop-up transfer balls allow easy movement of lamination plates for pin alignment.

- Lamination pins are placed into the bottom plate until only 1/8” petrude above the plate.

- Operator control allows Lamination pins to be extended above the first layer at will, allowing for ease of innerlayer loading.

- Max. lamination plate 25" x 28" Min. 9" x 9".

Operation

- Lamination plates are brought into place on registration stops.

- Pneumatic pop-up transfer balls are lowered to allow lamination plates to be stationary.

- Lamination pins are driven through tooling holes until pins are approximatly 1/8” above lamination plate.

- After the first innerlayers have been placed flush with pins, the operator indexes pins with foot pedal in the up direction to expose tooling pins for the next layers.

- When innerlayer placement is complete, the operator raises the tooling pins in the maximum up position for upper lamination plate placement.