Advantages of the LS-450

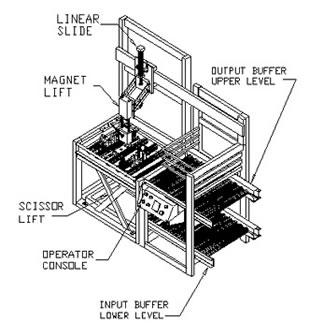

The C.A.PICARD® buffered lay-up station provides manufacturers the ability to greatly improve the productivity and yield of their lamination process. Through thoughtful ergonomic design, lay-up is greatly simplified. The system is easily configured to match your operational layout. Buffered input and output area further increase operator efficiency. The overall result is increased operator productivity and reduction of handling damage and particulate contamination.

Specifications

- Automatic lamination plate delivery.

- Semi-automatic lamination plate lifter with safe-hold magnet.

- Adjustable pin stops.

- Automatic finished book out-feed.

- Lamination plate sizes from 10"x12" to 24"x30".

- Larger lamination plate sizes are available.

- Mobile lay-up cart LSC-100 docks to lay-up station.

- Five adjustable shelves.

- Pull out separator / CAC shelf.

- Input and out buffer storage.

Operation

- Work order kits are loaded on a mobile cart LSC-100.

- Transport and dock the kit cart to the lay-up station.

- Retrieve kitted pre-preg, inner-layers, separator plates, CAC, and load leveler from easily accessible storage locations.

- Request lamination plate set for automatic delivery.

- Utilize the safe-hold magnet to lift and place the top lamination plate.

- Actuate the indexing pin stops.

- Build the work order by pulling product from the ergonomically placed shelves.

- Automatically send the finished book out to the press area.