Less expensive - longer-lasting - quicker

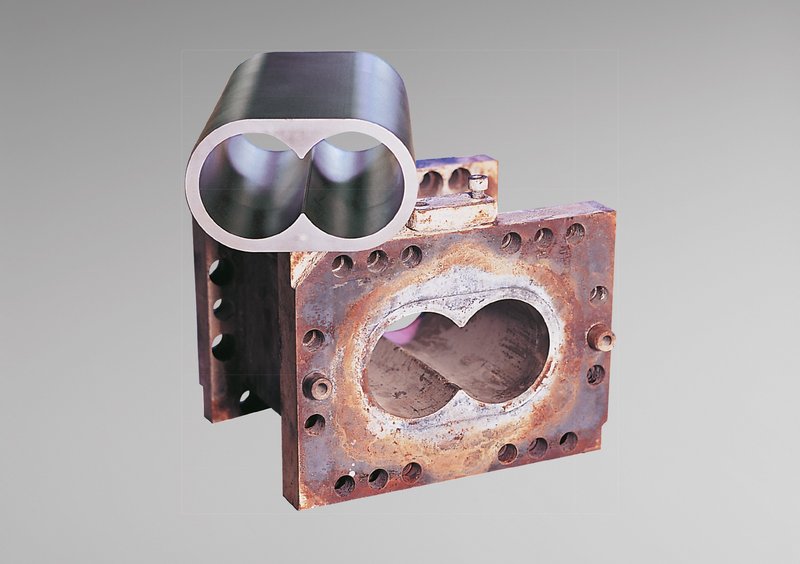

When C.A.PICARD® performs a barrel repair service, our customers receive a completely overhauled barrel in return, without the need to manufacture a new external body.

During the acceptance process, the used, worn barrel is examined and the flow through the cooling channels is tested. At this point, a decision is made as to how to proceed with the general overhaul.

On receipt of the order, the worn liner is removed, the cooling channels are also flushed and undergo pressure testing. Each barrel is issued with a sequential repair number. As the repair progresses, bores and threads are re-machined and the entire external body is cleaned using a suitable blast medium. Once the external body has been restored to as-new condition, the newly manufactured wear liner is inserted into the heated external body and the sealing faces are ground. The final stage is the outgoing inspection, which is conducted using a 3D measuring instrument in a climate-controlled room, during which all geometric data is checked. Prior to delivery, the refurbished barrel is checked for leaks in the cooling channels in a pressure test again. Only then can we be certain that our customers will receive a barrel from us that is not only in virtually as-new condition, but also meets all safety requirements.