The right tool matters

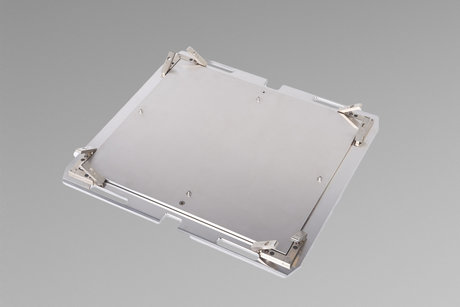

The precision and quality of a multi-layer circuit is, among other things, largely determined by the press tool. Therefore, selection and design of the tool is of utmost importance. It must meet the highest requirements in regards to precision of the hole distances, hole dimensions (for PinLam), parallelism, and flatness.

| Carrier plates, Top plates, Bonding plates | ||||

|---|---|---|---|---|

| Steel quality: | DIN 42 CrMo4 AISI 4140 H | DIN 50 CrV4 AISI 6150 H | RHCS 50 DIN X20CrMo13 | |

| Hardness: | 40 ± 2 HRC | 40 or 50 ± 2 HRC | 50 ± 2 HRC | |

| Thermal expansion coefficient: | 12 x 10-6 / °C | 11 x 10-6 / °C | ||

| Heat conductivity: | 42 W/mK | 25 W/mK | ||

| Working temperature: | ≤ 400 °C | ≤ 400 °C or | ≤ 400 °C | |

| Dimensions and tolerances | Standard | Premium (for all versions) | ||

| Length / Width: For large formats > 2000 mm: | ± 0.5 mm + 3-5 / -0 mm | |||

| Thickness: | ± 0.2 mm | |||

| Hole-to-hole tolerance for registration holes: | ± 0.02 mm | ± 0.012 mm | ||

| Wire cut registration slots: | on request | |||

| Flatness: | 0.2 - 3 mm depending on size and thickness | |||

| Parallelism: For large formats > 2000 mm: | ≤ 0.03 - 0.05 mm ≤ 0.1 mm | |||

| Surface finish: | Grit 80 Ra ca 1.2 - 2.50 µm | |||

| Available thickness: | 2.0 - 15.0 mm | up to 10 mm | ||

Press plates with wire-cut registration holes on request. Variations to above mentioned tolerances and standard specifications possible on request. Subject to changes due to technical improvements without prior notice.