Even for separator plates time does not stand still

The life time of separator plates for multilayer production is not only affected by high stresses during the pressing process Separator plates are also prone to get damaged by handling and cleaning processes leading to premature repair expenditures and defects.

C.A.PICARD® International, an established supplier of high quality press tools and separator plates for multilayer production has invested considerable resources into the development of a suitable material for multilayer separator plates. During this development market requirements as well as technical and process related demands have been taken into account for both plate and multilayer manufacturing.

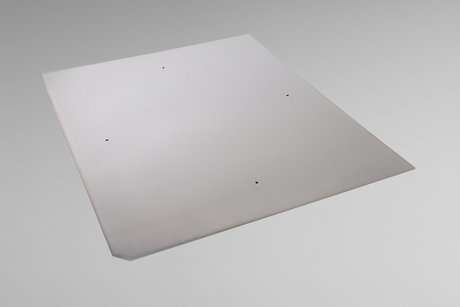

C.A.PICARD® separator plates

- Trouble-free production is guaranteed due to no distortion caused by variations in temperature

- Refurbishing is available quickly and at favourable costs

- High heat conductivity (less input of energy and time)

- Favourable TEC (thermal expansion coefficient)

- High corrosion resistance

- High hardness (50 HRC = longer life time)

- Usable for all types of cleaning / brushing machines

| Separator plates with laser cut registration holes | ||

|---|---|---|

| Steel quality: | RHCS 50 DIN X 20 CrMo 13 | RHCS 40 DIN X 10 CrNi 18-8 |

| Hardness: | 50 ± 2 HRC | 45 ± 2 HRC |

| Thermal expansion coefficient: | 11 x 10-6 / °C | 17 x 10-6 / °C |

| Heat conductivity: | 25 W/mK | 15 W/mK |

| Working temperature: | ≤ 400 °C | ≤ 280 °C |

| Dimensions and tolerances | ||

| Length / Width: | ± 0.5 mm | |

| Thickness: | ± 0.1 mm | |

| Hole-to-hole tolerance for registration holes: | ± 0.05 mm | |

| Tolerances for registration holes: | + 0.1 mm - 0 | |

| Flatness: | ≤ 3 mm/m | |

| Parallelism: | ≤ 0.03 mm | |

| Diagonal tolerance: | 2.00 mm | |

| Surface finish: | CAP Finish 5 Ra ≤ 0.14 μm, Rz ≤ 1.50 μm | |

| Available thickness: | 1.0 - 2.0 mm | |

Separator plates with wire-cut registration holes on request. Variations to above mentioned tolerances and standard specifications possible on request. Subject to changes due to technical improvements without prior notice.