Advantages of the BT-50

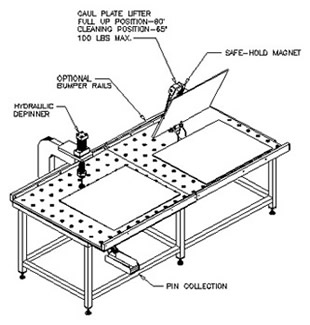

The C.A.PICARD® breakdown station improves your productivity by speeding up the process of depinning and disassembling lamination kits. Additionally, damage to expensive lamination tooling is virtually eliminated. Provides ergonomic improvements for operator safety.

Specifications

- Up to 45"x48" ball tables on advanced model 36"x36" on standard model

- Up to 2.5 inch thick printed circuit board lamination packages

- Guided depinning pin

- Quick change collet holds depinner pin

- Spring loaded stripper nose strips bushing from depinner pin

- Sized to remove up to ¼" lamination pins

- Easy removal pin collection bin

- 15" throat depth on advanced model. 8" throat depth on standard model

- Ball top table dimensions are optional

- 100 pound lamination plate lifter

- Exposes internal surfaces for cleaning

Operation

- Place template over book top lamination plate.

- Align template bushing under the nose of the depinner.

- Depress the press foot pedal for the depinning down stroke.

- Release the foot pedal to retract the depinner.

- Lower the lamination plate lifer by selecting the down switch and activating the dual palm button.

- Engage the safe magnet by swinging the dipole magnet arm 180 degrees.

- Lift the top lamination plate by selecting the up switch and activating the dual palm buttons.

- Break the book down and clean the lamination plates interior surface.

- Return the top lamination plate.

Contact C.A.PICARD® directly so we can help to specify a system that will maximize your productivity.