Advantages of the LS-550

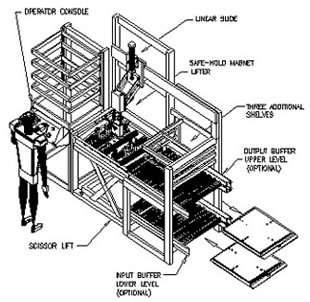

The C.A.PICARD® modular lay-up station provides manufacturers the ability to greatly improve the productivity of their lamination process. By combining shelf and lamination plate input / output options the system is easily designed to match your operation. Through the thoughtful ergonomic design lay-up is greatly simplified. The result is increased operator productivity and reduction of handling damage and particulate contamination.

Specifications

- Five adjustable shelves

- Three permanent shelves

- Automatic lamination plate in feed and book out feed

- Adjustable pin stops

- Max. lamination plate 24" x 30" Min. 10" x 12"

- Semi-automatic lamination plate lifter with safe-hold magnet

- 480 VAC 3 phase 15 amps

- 80 PSI air 2 cfm.

Operation

- Lamination plate sets enter on the lower level.

- Scissor lift brings the plate set to an ergonomic height.

- Safe magnet automatically lifts and stores the top lamination plate.

- Operator actuated pin stops.

- Five-product storage shelves on the left e.g. pre-preg, load leveler, kitted inner layers.

- Three storage shelves on the right for foils and separators.

- Finished books exit on the top level.

- Automatic delivery and buffering of lamination plate sets.

- Automatic delivery and buffering of finished books.

- Carrier tray or non carried lamination plate compatible.

- Semi-automated versions available.

- Shelf carts options available.